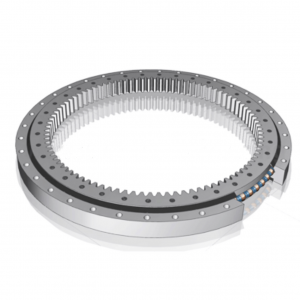

Umsesane obhityileyo ophethe izixhobo zangaphakathi 062 series

| Umzekelo | Wght | Imilinganiselo(mm) | Ukunyuka imilinganiselo(mm) | Idatha yeGear | Ukucaciswa kwe-Axial | Ukususwa kweRadial | |||||||||||||

| kg | D | de | H | DI | D2 | na | φ | M | t | d | m | z | km | b | Umthwalo ukuvumela KN | Layisha max KN | |||

| 062.20.0414 | 31 | 486 | 326.5 | 56 | 460 | 375 | 24 | 13.5 | 12 | 20 | 335 | 5 | 67 | -0.8 | 45.5 | 13.54 | 27.08 | ≤0.28 | ≤0.24 |

| 062.20.0544 | 42 | 616 | 445.2 | 56 | 590 | 505 | 32 | 13.5 | 12 | 20 | 456 | 6 | 76 | -0.6 | 45.5 | 16 | 32.00 | ≤0.30 | ≤0.26 |

| 062.20.0644 | 50 | 716 | 547.2 | 56 | 690 | 605 | 36 | 13,5 | 12 | 20 | 558 | 6 | 93 | -0.6 | 45.5 | 15.62 | 31.24 | ≤0.30 | ≤0.26 |

| 062.20.0744 | 58 | 816 | 649.2 | 56 | 790 | 705 | 40 | 13.5 | 12 | 20 | 660 | 6 | 110 | -0.6 | 45.5 | 15.32 | 30.64 | ≤0.30 | ≤0.26 |

| 062.20.0844 | 69 | 916 | 737.6 | 56 | 890 | 805 | 40 | 13.5 | 12 | 20 | 752 | 8 | 94 | -0.8 | 45.5 | 20.80 | 41.60 | ≤0.30 | ≤0.26 |

| 062.20.0944 | 76 | 1016 | 841.6 | 56 | 990 | 905 | 44 | 13.5 | 12 | 20 | 856 | 8 | 107 | -0.8 | 45.5 | 20.49 | 40.98 | ≤0.30 | ≤0.26 |

| 062.20.1094 | 91 | 1166 | 985.6 | 56 | 1140 | 1055 | 48 | 13.5 | 12 | 20 | 1000 | 8 | 125 | -0.8 | 45.5 | 20.16 | 40.32 | ≤0.30 | ≤0.26 |

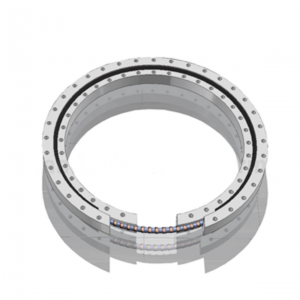

UkuKhanya Uhlobo lokuSlewing Bearing-Isisombululo sezicelo zakho zaMandla aVuselelwayo

Ukuba ujonge isisombululo esinokwethenjelwa nesisebenzayo kwizicelo zakho zamandla avuselelekayo, ke uLwahlu lwethu lokuKhanya lwe-Slewing Bearing lolona khetho lufanelekileyo kuwe. Ngomthamo wayo ophezulu womthwalo kunye nokujikeleza okugudileyo, le mveliso ilungele uluhlu olubanzi lwezicelo zamandla ahlaziyekayo, kubandakanywa ii-injini zomoya kunye neetraki zelanga.

Uhlobo lwethu lokuKhanya lwe-Slewing Bearing lwenziwa kwizinto ezikumgangatho ophezulu kwaye zenzelwe ukujamelana neemeko ezinzima. Kukwalula ukuyifaka kwaye ifuna ukulungiswa okuncinci, iyenza ibe sisisombululo esineendleko ezifanelekileyo kwishishini lakho.

Ngoko kutheni ulinda? Qhagamshelana nathi namhlanje ukuze ufunde ngakumbi malunga noLuhlu lwethu lokuKhanya lwe-Slewing Bearing kunye nokuba lunokukunceda njani uphucule izicelo zakho zamandla ahlaziyekayo kunye nokwandisa inzuzo yakho.

Ufakelo kunye noLondolozo lweeBearings zokuKhanya-duty Slewing

Ufakelo olufanelekileyo kunye nokugcinwa kubalulekile ekuqinisekiseni ukusebenza kwexesha elide kunye nokuqina kweebheringi zokukhanya. Ngethuba lokufakela, ukuthwala kufuneka kuhambelane ngokufanelekileyo kwaye kukhuselwe ukukhusela ukungahambi kakuhle kunye nokugqoka kwangaphambili. Ukugcinwa rhoqo, okufana ne-lubrication kunye nokuhlolwa, kuyafuneka kwakhona ukuze kuqinisekiswe ukuba i-bearing isebenza kwi-peak performance. Naziphi na iimpawu zokugqoka okanye umonakalo kufuneka zibhekiswe ngokukhawuleza ukukhusela umonakalo ongakumbi kunye nokungaphumeleli.

Uphuhliso lwexesha elizayo kwi-Light-duty Slewing Bearings

Njengoko itekhnoloji iqhubela phambili, kukwanjalo nokuba nako ukwenza iibheringi zokukhanya. Uphuhliso lwexesha elizayo lunokubandakanya ukusetyenziswa kwezinto eziphambili, ezinjengee-composites kunye neekeramics, ukunciphisa ngakumbi ubunzima kunye nokwandisa ukuqina. Ubuchule obutsha bokwenza, obufana noshicilelo lwe-3D, lunokusetyenziselwa ukuyila uyilo oluntsonkothileyo nolwenzelwe wena. Ukongeza, ukuqhubela phambili kwitekhnoloji ye-sensor kunokuvumela ukujonga ixesha lokwenyani lokuthwala ukusebenza, ukuvumela ukugcinwa kwangaphambili kunye nokunciphisa ixesha lokuphumla.